PRODUCTS

Location:Home > PRODUCTS > Heat Shrinkable Tubes Series > PE Environmental-Friendly Shrinkable Tubes > Yellow Green Heat Shrinkable Tube

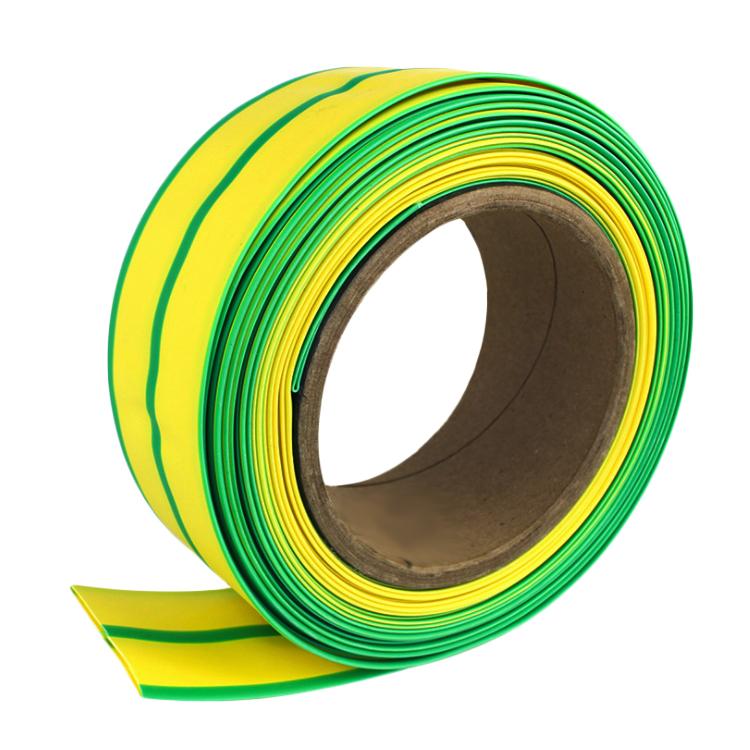

Yellow Green Heat Shrinkable Tube

Yellow & Green shrinkable tube is made from high quality dual colors polyolefin materials. It has a performance of flexible, high combustion resistance, quick shrinkage, durable colors, stable, etc.

·Application temperature: -55℃ ~ 125℃

·Shrinking Temperature: Start at 70℃, and shrunk completely at 120℃ .

·Radial shrinkage ratio: 2:1.

·Vertical shrinkage ratio: ≤8%

·Merit: Flexible, high combustion resistance, quick shrinkage, durable colors.

·Convenient to use: heat by oven or hot air gun.

·Standard color: yellow and green in each interval.

Characteristics | Performance | Test Items | Performance Indicator |

Continue Use Temperature | -55 ℃ ~125 ℃ | Flame Retardancy | Pass |

Tensile Strength | ≥10.4 MPa | Breakdown Strength | ≥15KV.mm |

Vertical Shrinkage | 85% | Volume Resistivity | 10¹ ⁶ Ω.m |

Data Table:

Size (mm) | Before Shrink | After Shrank | Standard Package | Range of Application (mm) | ||||

I.D. (mm) | Average Layer Thickness | I.D. (mm) | Average Layer Thickness | m/roll | roll/box | package specification(cm) | ||

Φ2.0 | 2.5± | 0.20±0.05 | 1.00 | 0.40±0.05 | 200 | 15 | 46*46*43 | 1.2~2.3 |

Φ3.0 | 3.5± | 0.25±0.05 | 1.50 | 0.40±0.05 | 200 | 11 | 46*46*43 | 1.7~2.3 |

Φ4.0 | 4.5± | 0.25±0.05 | 2.00 | 0.44±0.05 | 200 | 7 | 46*46*43 | 2.2~4.2 |

Φ5.0 | 5.5± | 0.25±0.05 | 2.50 | 0.50±0.08 | 100 | 9 | 46*46*43 | 2.7~5.2 |

Φ6.0 | 6.5± | 0.25±0.05 | 3.00 | 0.55±0.08 | 100 | 7 | 46*46*43 | 3.2~6.3 |

Φ7.0 | 7.5± | 0.25±0.05 | 3.50 | 0.55±0.08 | 100 | 14 | 46*46*43 | 3.7~7.3 |

Φ8.0 | 8.5± | 0.30±0.05 | 4.00 | 0.58±0.08 | 100 | 13 | 46*46*31 | 4.2~8.3 |

Φ10. | 10.7± | 0.30±0.05 | 5.00 | 0.60±0.08 | 100 | 11 | 46*46*31 | 5.2~10.3 |

Φ12.0 | 12.7± | 0.30±0.08 | 6.00 | 0.65±0.08 | 100 | 10 | 46*46*31 | 6.2~12.3 |

Φ13.0 | 13.7± | 0.30±0.08 | 6.50 | 0.65±0.08 | 100 | 9 | 46*46*31 | 6.7~13.3 |

Φ16.0 | 16.7± | 0.35±0.10 | 8.00 | 0.75±0.08 | 100 | 8 | 46*46*29 | 8.2~16.3 |

Φ20.0 | 21.4± | 0.35±0.10 | 10.00 | 0.82±0.15 | 100 | 6 | 46*46*31 | 10.2~21 |

Φ25.0 | 26.5± | 0.40±0.15 | 12.5 | 1.00±0.15 | 50 | 6 | 46*46*29 | 12.8~26 |

Φ30.0 | 31.5± | 0.45±0.15 | 15.0 | 1.05±0.15 | 50 | 5 | 46*46*31 | 15.2~31 |

Φ35.0 | 36.5± | 0.45±0.15 | 17.5 | 1.15±0.15 | 50 | 4 | 46*46*29 | 18~36.0 |

Φ40.0 | 41.5± | 0.50±0.15 | 20.0 | 1.20±0.15 | 50 | 4 | 46*46*31 | 21~41.0 |

Φ50.0 | 51.5± | 0.50±0.15 | 25.0 | 1.20±0.15 | 25 | 5 | 31*31*42.5 | 26~50.0 |

Φ60.0 | ≥60.0 | 0.60±0.15 | 30.0 | 1.55±0.15 | 25 | 4 | 31*31*42.5 | 31~59.0 |

Φ70.0 | ≥70.0 | 0.60±0.15 | 35.0 | 1.60±0.15 | 25 | 3 | 31*31*36 | 36~68.0 |

Φ80.0 | ≥80.0 | 0.60±0.15 | 40.0 | 1.70±0.15 | 25 | 3 | 31*31*42.5 | 41~79.0 |

Φ90.0 | ≥90.0 | 0.70±0.15 | 45.0 | 1.90±0.15 | 25 | 2 | 31*31*36 | 46~89.0 |

Φ100.0 | ≥100.0 | 0.70±0.15 | 50.0 | 2.10±0.15 | 25 | 2 | 31*31*36 | 50~98.0 |

Φ120.0 | ≥120.0 | 0.70±0.15 | 60.0 | 2.20±0.15 | 15 | 2 | 31*31*42.5 | 31~118 |