PRODUCTS

Location:Home > PRODUCTS > Metals Soldering Materials & W > Welding Machinery Equipment > High Frequency Induction Welder

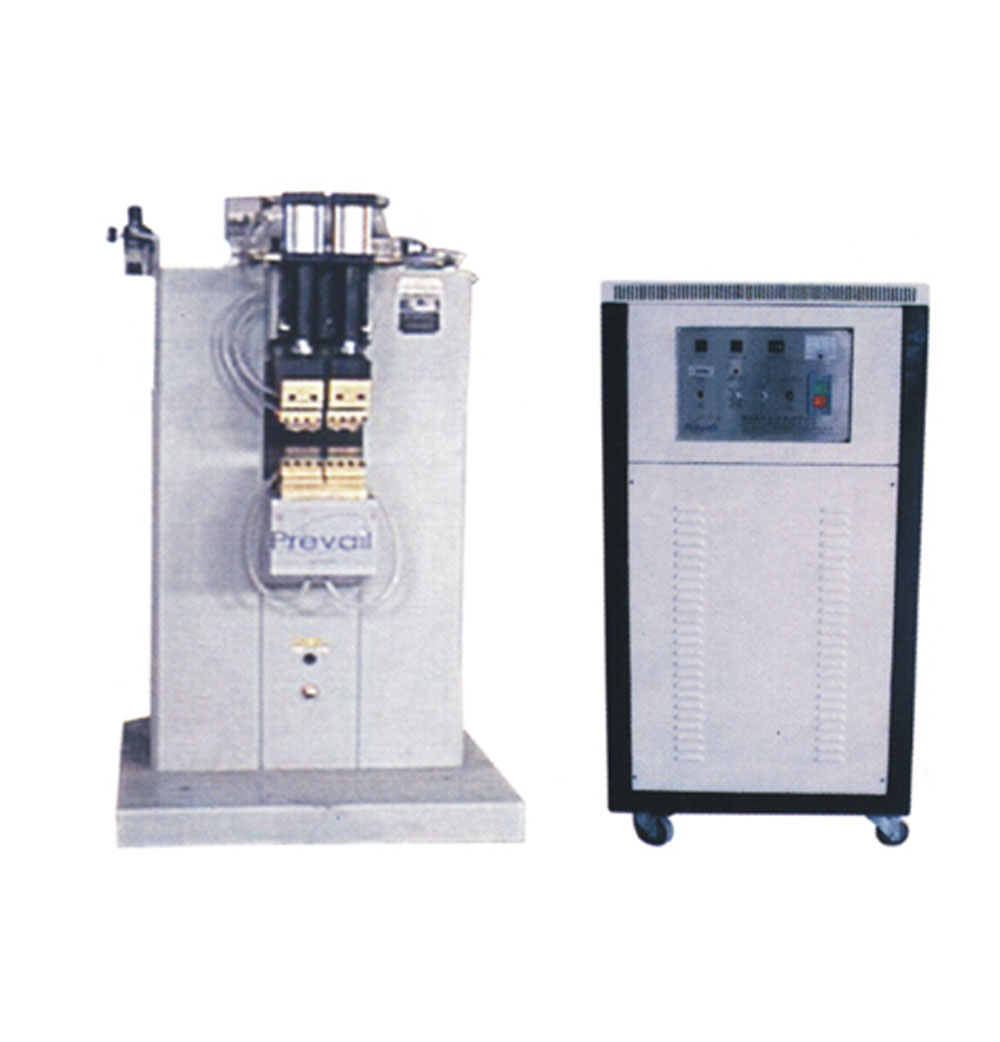

High Frequency Induction Welder

·MOSFET and Inverting technologies of First generation been used;

·Simple structure and light weight and lowest price;

·Simple to operate, A few minutes is enough to learn it;

·Simple to install, Installation can be done by unprofessional person;

·Advantages of the model with timer: the power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability;

·The separated models are designed to fit the dirty surrounding of some cases.

Applications:

·Brazing of the diamond blade tool;

·Brazing of the Machining tools;

·Brazing of the Micrometer;

·Brazing of Copper tube;

·Brazing of the connector;

·Heat treatment of small parts.

·Maximum input power: 7KW

·Oscillating frequency: 30100KHZ

·Input : 220V Single phase, 50 or 60HZ

·Cooling water desire: 0.2Mpa, 2 ~ 5 L/min

·Duty cycle: 80%

·Imer of the SP-15A and SP-15AB model: Heat time, Retain time

Cool time: 199Sec

·Cable length of the separated model: 2 meters

·Weight and size

Item | Weight (kg) | Size (cm) L × W × H |

SP-15 | 18 | 44 × 27 × 39 |

SP-15A | 20 | 46 × 20 × 44 |

15(A) BController | 14 | 46 × 20 × 44 |

15(A)BTransformer | 11 | 31 × 19 × 33 |