PRODUCTS

Location:Home > PRODUCTS > Coating Measurement Meters > Coating thickness Gages series > Coating Thickness Gauge 6000

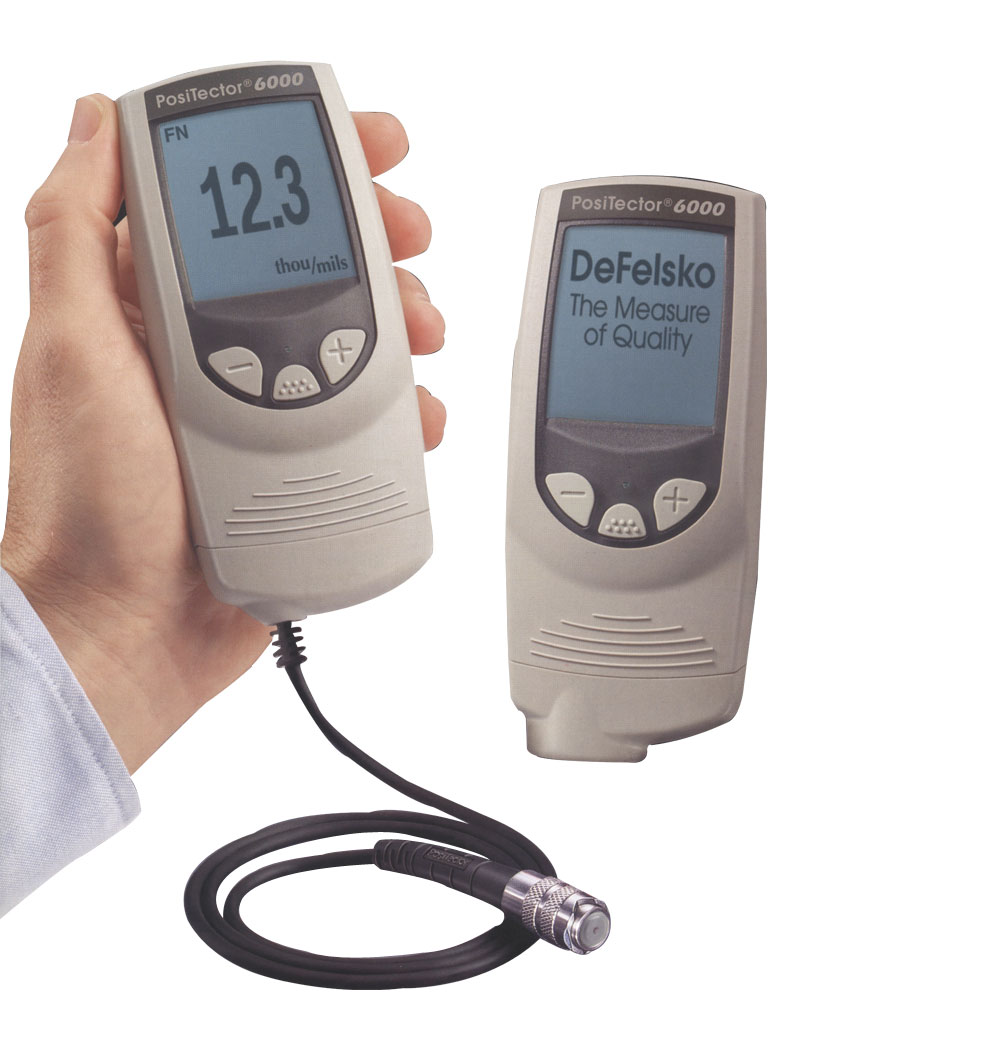

Coating Thickness Gauge 6000

• 3 buttons operation

• Automatically turn-off/on, double probe

• Average return to zero, use on rough surface

• Reset function restore it quickly to original factory state.

• Simple introduction on the back

• Resistant to acid, oil, solvent, dust and water

• Anti-vibration when reading

• One year guarantee

• Can provide calibration process and standard plate

• Easily adjust to any known thickness

Good for having test result at noisy environment

Rotating display: particular rotating display, easy to read hand-held or on desktop

Convenient to operate by one hand

Statistic type(2)capable of all features of standard type, and prompt when exceeding

• HI-RES mode: Enhance reading resolution when running a high precise measurement

• Can set inner automatically turn-off time

• Reading storage up to 250 pcs

• IR interface installed, printing by a wireless printer (bargain price)

• Separated probes

Various probes are switchable for different tests

• NIST Standard

• Calibration certificate included

• Provide a safe, convenient bag

• Build/note/edit group, parts, operator, application name can be stored

• Provide RS-232 cable can input data into windows, printer or data collector

• Provided PosiSoft analyze software, run under windows

• IR printing interface installed

• It can modify computer user, spare part grouping and establish introduction, explain.

• Display, file, graphic data is thick as 5 films

• Can print basic diagram and cylinder diagram

• Provide data and time information

• Use regular format like ASC II that can save data into computer

• Ideal thickness monitor of coating and analyze software

• SSPC PA-2 mode, calculate average of a group of reading

• Reading can be output or save for processing next time

• Provide PosiSoft under windows

• Provide RS-232 cable use for transporting data to PC, printer or collector

Clock installed, each storage reading will be labeled date and time

Extra from Memory type (3)

• Input hints

• Show and print diagram

• Use regular format to save data like ASCII code

• Convenient to monitor and analyze film thickness with various language

• Every separated probe can track NIST certificate

• Gold plating durable plug with lock is good for industrial environment

• Excellent breakage-proof soft cable

• Lengthen cable (up to 75m) for long distant measurement

• All standard probes is available use under water

• All constant voltage probe can use V type groove and bevel fixing in order to measure inside or outside of tube

• Micro probe (iron material or non-ferrous metal) work on tiny or surface that hard to approach. 0o, 45o, 90o, 3 configurations with different probes is suitable for widely use.

Micro probe can transfer to constant voltage and use 0 probe to measure tiny flat or curved surface.

• Automatically identify surface of iron/non-ferrous metal

• Decrease influence by fault operation

• Can measure zincification layer on steel, film of oxide on aluminum, coating on metal, chromium,layer on steel

• Specified “N-LOCK” mode can measure magnetic materials like transparent coating on nickelage copper material

• Provide double probe and separated probe

• Ideal choice for measuring powder coating

Memory type ( 3 ) gauge, display sample at grouping mode

Measure reading divide up to 200 groups

Batch1 | Cal | |

n50 | 21.00x | 3.61 σ |

42.0x | 20.1 ↓ | |

F | 20.1 | |

Show iron/non-ferrous material

Multi-function:

Thin cladding from micro component to big size thick coating

Probe/part fixed basement: make sure the accurate repeated location in measuring

Double duty probe cover |

Double probe cover with V type groove, more stable when measuring with it open ← Various materials calibration information |

Order Introduction |

Probe information (one probe for each gauge, extra probe need to purchase) |

Order Introduction

Description | Standard double type | Separated probe | 90°Standard probe use at narrow space | Standard probe use at soft materials | Measuring film of aluminum oxide | Micro probe*, the smallest probe use at tiny piece and hard approaching surface | Double type, separated type of thick epikote, rubber, fireproof materials | Large measure range probe specified in thick film* | |||

Non-magnetic materials of iron material, steel and cast iron | |||||||||||

F1 | FS1 | FRS1 | SPFS1 | ||||||||

F2 | FS2 | FRS2 | SPFS2 | FOS2 | F45S2 | F9052 | FT2 | FTS2 | FHS2 | ||

F3 | FS3 | FRS3 | SPFS3 | FOS3 | F45S3 | F9053 | FT3 | FTS3 | FHS3 | ||

Insulated coating of non-ferrous metallic aluminum and copper | |||||||||||

N1 | NS1 | NRS1 | |||||||||

N2 | NS2 | NRS2 | NAS2 | NOS2 | N45S2 | N90S2 | NTS2 | NHS2 | |||

N3 | NS3 | NRS3 | NAS3 | NOS3 | N45S3 | N90S3 | NTS3 | NHS3 | |||

Compound type for all metal | |||||||||||

FN! | FNS1 | FNRS1 | |||||||||

FN2 | FNS2 | FNRS2 | FTNS2 | ||||||||

FN3 | FNS3 | FNRS3 | FTNS3 | ||||||||

Measure range | 0-1500μm 0-60mils | 0-625μm 0-25mils | 0-6mm 0-250mils | 0-20mm 0-750mils | |||||||

Precision(error) | |||||||||||

±(1μm+1%)0-50μm | ±(0.5μm+1%)0-100μm | ±(0.01mm+1%) 0-2.5mm | ±(0.02mm+1%) 0-6mm | ||||||||

±(2μm+1%)>50μm | ±(2μm+3%)>100μm | ±(0.01mm+3%) 0>2.5mm | ±(0.02mm+3%) >6mm | ||||||||

±(0.05mils+1%)0-2mils | ±(0.01mils+1%)0-4mils | ±(0.5mils+1%) 0-100mila | ±(1mils+1%) 0-250mils | ||||||||

±(0.1mils+1%)>2mils | ±(0.1mils+3%)>4mils | ±(0.5mils+3%) >100mils | ±(1mils+3%) >250mils | ||||||||

DeFelsko Standard Edition | |||||||||||

CAL-S1 | CAL-S2 | CAL-P1 | CAL-P2 | ||||||||

CAL-A1 | CAL-A2 | CAL-P1 | CAL-P2 | ||||||||

“0” after *F 、 N: flat contact by probe; “45”: contact at 45 angle; “90”: contact at 90 angle.